Principles of Modern SCADA Systems: Oil Well Pump

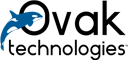

The laboratory branch is designed to study the design principles of modern SCADA systems, the operation of automation system of typical objects of oil and gas industry and emulation of sensors that serve to monitor and control the objects. The stand is based on the object mathematical model, which helps to simulate various situations of its work under the control of SCADA system.

Learn more

Stationary System of Vibration Monitoring and Diagnostics

The stationary system of vibration monitoring and diagnostics of gas pumping units (GPU) of the compressor plant is based on National Instruments’ technologies. The system is designed to automate the continuous and periodic monitoring processes of vibration condition analysis of GPU.

Learn more

Cluster Pump Station Automation System

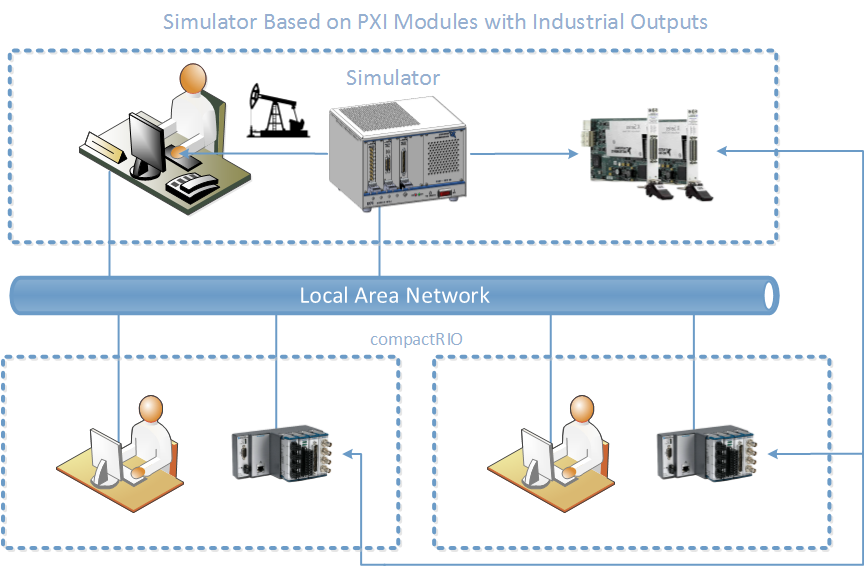

Due to depletion of oil resources, increasing power costs and other factors oil companies are trying to reduce well maintenance costs and further improve the manufacturing efficiency. Therefore, modern approach to oil production automation dictates strict requirements for cluster pump station (CPS) control and monitoring software and hardware systems.

Learn more

Multiphase Flowmeter DIP

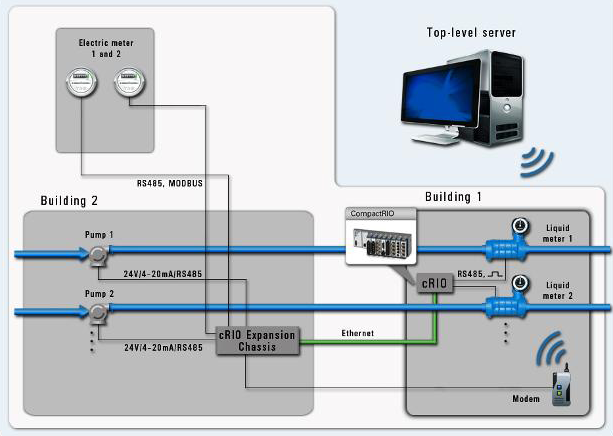

The software is developed by «Ovak Technologies» upon technical specification of «Petroleum Technology» company. The solution is based on National Instruments sbRIO Controller.

Learn more

Oil Well Pump Control System Foton

In order to increase production rate, a special system is designed for monitoring and intellectual control of downhole well pump with a specific algorithm of non-stationary pressure and water cut a depth of the well.

Learn more

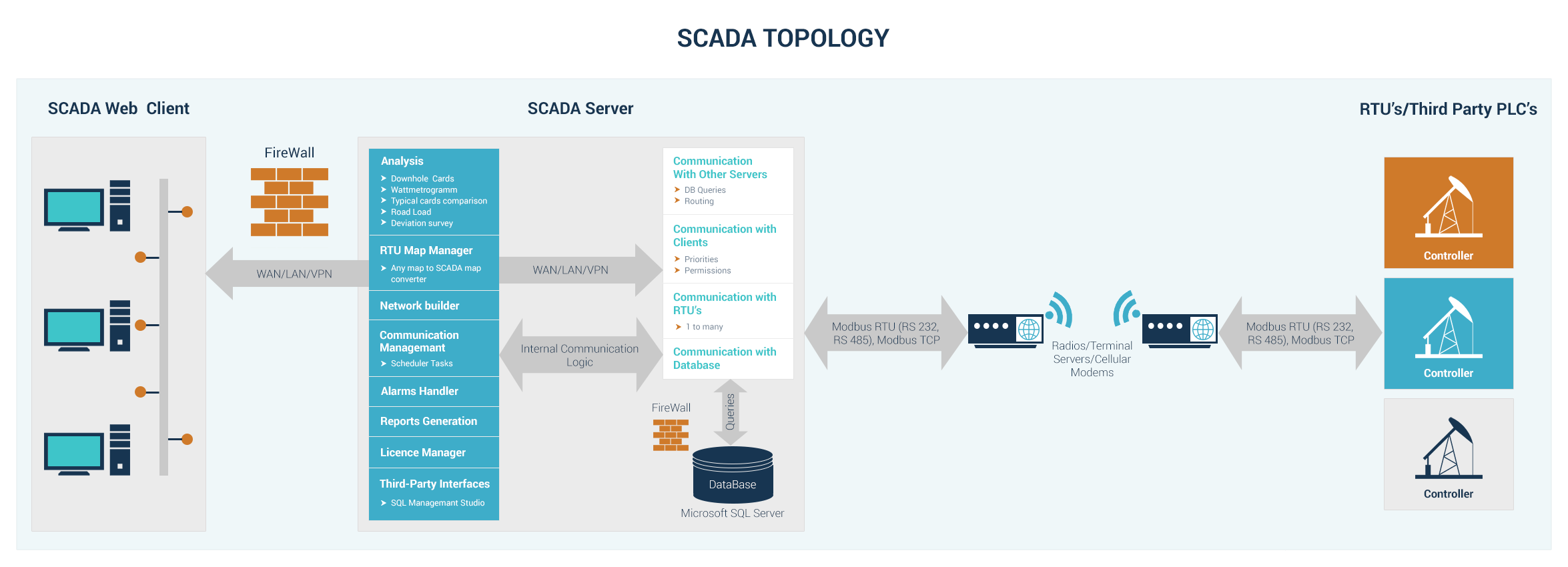

SCADA System for Oil Pumping Rig RTUs

The system is designed to diagnose, monitor and control technological processes (TP) of downhole equipment in real-time. The system provides a multi level and multi user access to technological and service staff.

Learn more

Oil Well Pump Control System

Modern approach to the automation to the automation processes in oil industry dictates stringent requirements for the hardware/software systems of control and management of downhole pump. The controller is designed for downhole pump real-time control. The data is processing and transferring to the operator console for storage and remote control of the controller.

Learn more